Pre-Transport Preparation

Every CNC machine move requires precision and care. This guide breaks down the critical steps from initial measurement to final delivery, ensuring your valuable equipment is transported with expertise and safety.

Accurate Measurement:

Begin by obtaining precise dimensions (length, width, height) and weight of your CNC machine. This data is crucial for selecting the appropriate trailer type, planning the logistics of the route, and ensuring compliance with transportation regulations. Accurate measurements help in assessing whether a standard flatbed, step deck, or double drop trailer is needed based on the size and weight of your machine.

Visual Documentation:

Before pickup, request current photos of the machinery to assess its condition and preparation for shipping. This step is vital for several reasons:

- Condition Verification: Ensures the machinery has been prepared and packaged to prevent damage during transport.

- Accountability: Provides a baseline record of the machine’s condition before transit, useful in case of disputes or insurance claims arising from transport damage.

- Loading Preparation: Helps in pre-planning the loading process, including the type of equipment needed at the pickup site, such as cranes or forklifts, especially if the machine is large or awkwardly shaped.

Trailer Types Used For Transporting CNC Machines

Flatbed:

Loading Flexibility: Flatbed trailers are excellent for transporting large or heavy CNC machines. Their open design facilitates both side and overhead loading, allowing for flexibility using forklifts or cranes.

Stepdeck:

Accommodating Height: Stepdeck trailers offer an advantage for taller equipment that might not fit on a standard flatbed due to height restrictions. Their lowered deck facilitates easier loading and better center of gravity for tall machinery.

Double Drop:

Specialized for Oversized Loads: These trailers are specifically designed for very tall or extremely heavy machinery, featuring a central well that sits lower between the front and rear decks, accommodating even taller CNC machines without height compliance issues on roads.

Conestoga:

Protection and Loading Efficiency: Conestoga trailers are equipped with a retractable tarp system that provides excellent protection without contacting the machinery, making them ideal for delicate or high-precision equipment. They facilitate easy loading and unloading with a crane or forklift from the sides.

Width Limitations: It’s important to note that Conestoga trailers cannot accommodate machinery wider than 102 inches. If your CNC machine exceeds this width, an open deck trailer with appropriate tarps will be required to ensure the machine fits on the trailer correctly.

Dry Vans:

Enclosed Transport: Dry vans are best suited for smaller, more sensitive components or machines that require complete protection from external elements. They provide a secure, enclosed environment, protecting the contents from weather and road debris. Note: Dry Vans require a dock to unload, unless the equipment is loaded in the rear and the consignee has long enough forks to unload.

Requesting a Freight Quote

Freight Quote Preparation: When you’re ready to transport your CNC machine, provide your carrier with detailed information to receive an accurate freight quote. This includes:

Pick-up and delivery locations: Specify city and state.

Machine dimensions and weight: Essential for selecting the right trailer.

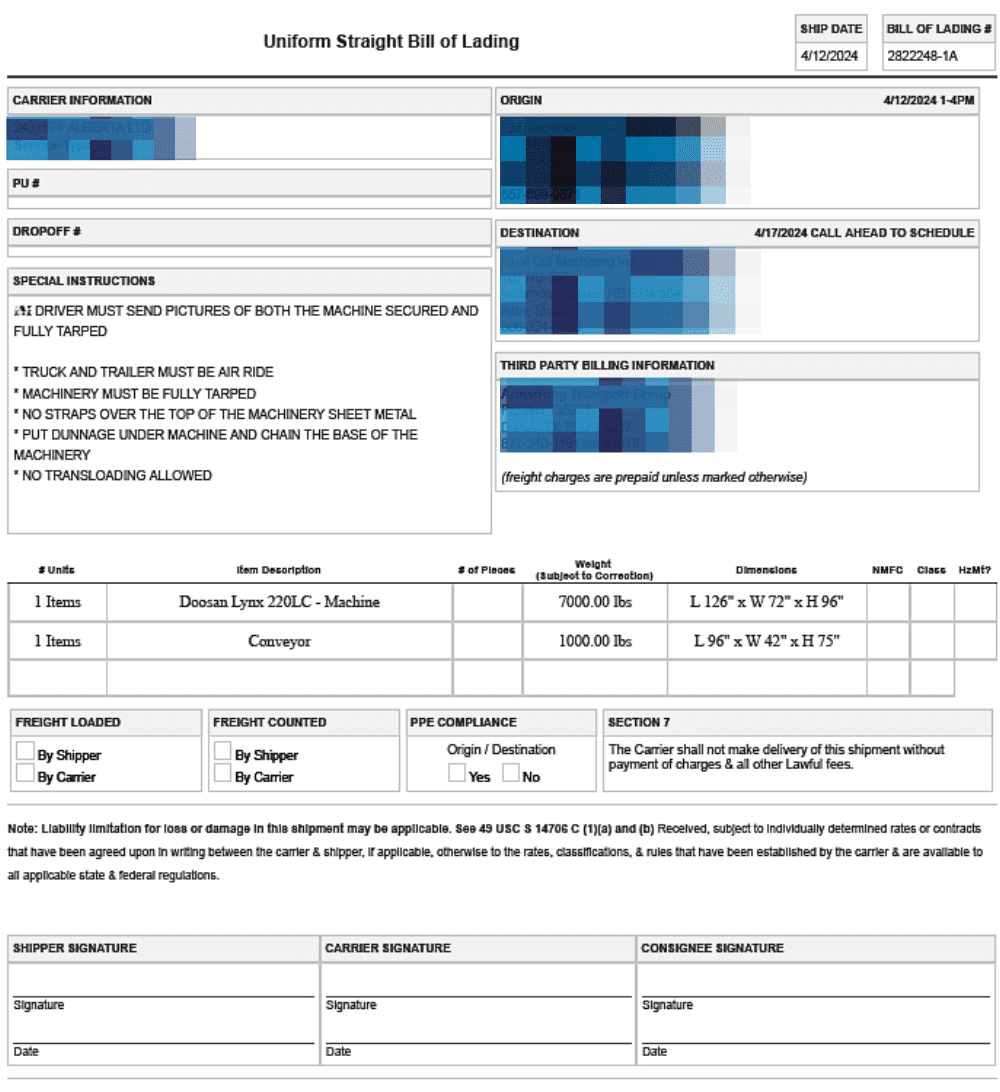

Special requirements: Note any specific needs such as air-ride suspension, dunnage, chains and binder, tarping requirements, and we recommend NO-TRANSLOADING once the machine is on the trailer to keep the machine from being handled multiple times during transit causing more chances of damage to the machine.

Value of the machine: Important for determining the level of insurance coverage needed.

Importance of Insurance Coverage

Insurance Options:

All-Risk Insurance: Offers comprehensive coverage against all potential risks, highly recommended for high-value CNC machinery, because sometimes the carrier will deny the claim and it’s backup, so you can sleep at night knowing your machine is fully insured.

Supplemental Insurance: Consider additional policies for specific risks associated with your machine’s transit. Discuss the machine’s value with your own in house insurance provider. Some customer likes using their own insurance knowing their agent has their companies best interest in mind.

Loading, Securing, and Documentation

Secure Loading Practices: Ensure the CNC machine is loaded onto an air-ride-equipped trailer, which is crucial for minimizing transit shock and protecting the machine’s integrity. Use dunnage to properly elevate and secure the base of the machine, ensuring it remains stationary during transport. It’s essential to avoid placing straps over any sensitive parts of the machinery to prevent damage.

Visual Confirmation of Securement: Request that the carrier provides photographs of the machine once it is secured and fully tarped on the trailer. This visual confirmation is critical for ensuring that the machine was loaded and secured, and tarped correctly.

Bill of Lading (BOL): A comprehensive Bill of Lading must be prepared, detailing all specifics about the cargo, including any pre-existing damages. This document is crucial for legal and insurance purposes and must be signed by both the shipper and the carrier at the time of pickup. The BOL serves as a key document to verify the condition of the machinery at the point of handover.

Communication and Delivery

Tracking and Updates: Make sure to ask for a tracking link and the driver’s contact information at the start of the transport. This allows you to monitor your shipment’s progress in real-time and address any concerns directly with the driver as needed.

Final Inspection and Unloading:

Inspect Upon Arrival: When your CNC machine arrives, you should conduct a thorough inspection. Any discrepancies should be documented on the Bill of Lading before unloading. This is crucial for any necessary insurance claims and ensures that any issues are acknowledged and addressed promptly.

Exploring Further Resources on CNC Machinery Transportation

To enhance your understanding of CNC machinery transportation and explore best practices, several online resources provide detailed information and expert insights:

- Machinery Movers Magazine – Offers updates and articles on the latest in machinery moving techniques and equipment. Visit Machinery Movers

- American Equipment & Fabricating Corp. – Provides resources and case studies on transporting heavy equipment, including CNC machines. Visit American Equipment & Fabricating Corp.

- ThomasNet – A comprehensive resource for finding information on different types of CNC machinery and suppliers. Visit ThomasNet

- Modern Machine Shop Online – Features articles, tips, and case studies on the practical aspects of CNC machine usage, maintenance, and transportation. Visit Modern Machine Shop Online

Types of Machinery Abound Transport Specializes In: Abound Transport handles a diverse range of CNC machines, including, but not limited to:

Haas Mills and Lathes

Doosan Mills and Lathes

Mazak Machining Centers

Hurco CNC Machines

Okuma Mills and Lathes

Mori Seiki Lathes

Fadal CNC Mills

Tormach Personal CNC (PCNC)

Matsuura Machinery

DMG Mori Machines