For High-Value Machinery, Learn Conestoga Specs & Dimensions

Looking for detailed Conestoga trailer specs and dimensions? Conestoga trailers provide the protection of an enclosed van with the loading flexibility of an open-deck trailer. Their rolling tarp system allows freight to be loaded from the top, sides, or rear while staying fully protected from weather and road debris, making them ideal for high-value machinery transport.

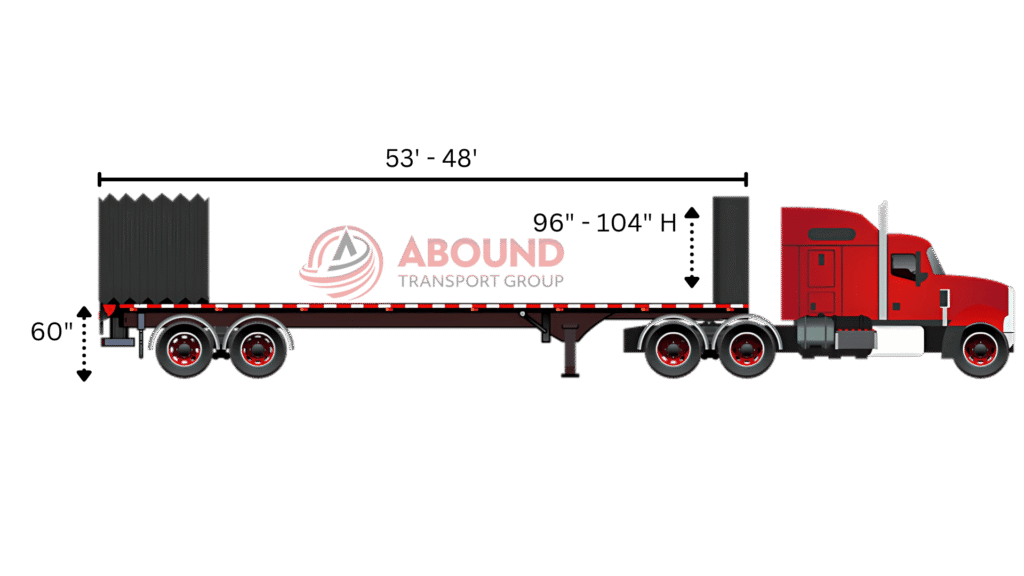

48′ – 53′ L

102″ W

~96″-104″ H

60″ H (dock height)

~47,000lbs

Commonly used for machinery, palletized goods, fabricated steel, or equipment requiring weather protection and air ride.

48′ – 53′ L

102″ W

96″ H

116″ H

42″ H

~44,000lbs

Commonly used for taller crated machinery, robotics, packaging lines, and equipment that needs both height clearance and secure, enclosed coverage.

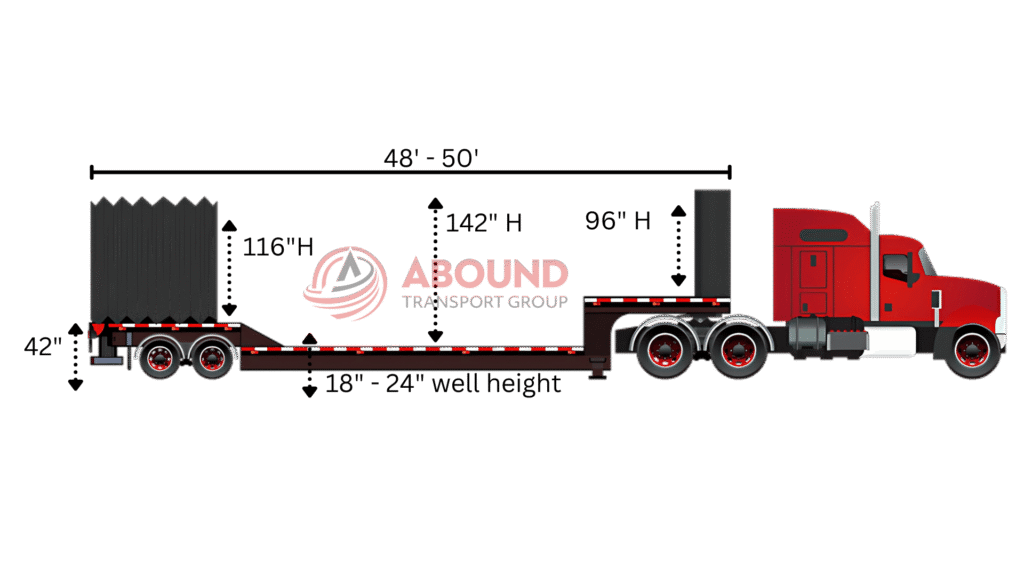

48′ – 50′ L

102″ W

96″ H

142″ H

116″ H

18″-24″ H

~35,000lbs

Commonly used for taller crated machinery, robotics, packaging lines, and equipment that needs both height clearance and secure, enclosed coverage.

💡 Pro Tip: For confirmation of Conestoga tarp system dimensions and clearance details, review the

Aero Conestoga System by Aero Industries

to ensure proper fitment and smooth loading.

A look at how we’ve moved flatbed, stepdeck and Double drop Conestoga loads recently

Conestoga trailers were developed as a solution to a common shipping challenge: how to protect freight from weather without giving up the loading flexibility of a flatbed. Traditional tarping was labor-intensive, time-consuming, and carried safety risks. To solve this, manufacturers created a rolling tarp system that could slide open and closed along tracks, similar to the old Conestoga wagon covers of the American West. The design allowed cargo to be loaded from the top, sides, or rear, then fully enclosed for transport. Today, Conestoga trailers are widely used for machinery, precision equipment, and freight that requires both accessibility and protection.

Proper securement ensures safety, compliance, and protection for your freight. Carriers follow FMCSA 393.100 cargo securement regulations and we use tools like highway to safe check carriers daily. Common Securement Tools:

for machinery, steel, and heavy freight

for finished goods and delicate cargo

for balance and elevation

We maintain clear communication with our carriers before every pickup, ensuring the correct tiedowns, edge protection, and equipment configuration are used based on the freight requirements. Each shipment is reviewed for proper weight distribution and safe routing to prevent delays and protect your equipment. Safety and compliance are prioritized from loading through final delivery.

💡 Pro Tip: For official securement regulations and tiedown requirements, review the FMCSA Cargo Securement Rules (49 CFR 393.100–393.136) . This ensures your shop, riggers, and yard personnel are aligned with the same safety standards used across North America.

Freight Quote

Coordinate

Generate BOL

Dispatch Driver

ATGFR8 Tracking

Delivery & POD

Our commitment to reliable service and partnership shows in our reviews. See why businesses trust us with their most critical shipments.

Freight: (2) Used Injection Molders – 15′ L x 5′ W x 6′ H – 15,000 each

Challenge: Same day delivery, couldn’t waste time tarping

Insights on Shipping, Trailer Types, and Logistics Trends

It protects from weather and damage — no tarp rash, faster load/unload.

Flatbed: 8'8", Step Deck: 9'8", Double Drop: 11'10"

Yes, if within height/width limits. For extra-large freight, we’ll advise an RGN or permit move.

Yes, nationwide — or we’ll work with your existing partners.

Yes — we offer direct and transload options into Canada and Mexico.

Slightly higher than a flatbed, but far less risk and damage cost.

Get expert guidance, real-time visibility, and top-tier protection.