Built for Heavy, High-Profile, and Specialized Loads

Double drop trailers feature an ultra-low center well that allows tall or heavy freight to travel safely within legal height limits. Their multi-level deck design provides stability, balanced weight distribution, and clearance flexibility that standard open-deck trailers cannot match.

Built for demanding, precision transport, double drops deliver reliable performance for oversized and specialized shipments across the United States, Canada, and Mexico.

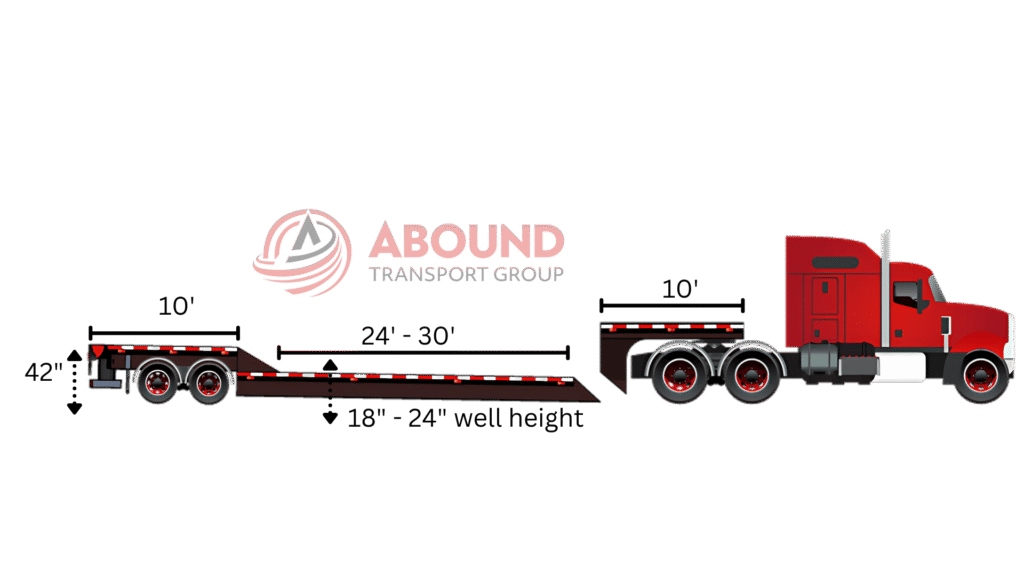

~10′ L x 102″ W

~24-30′ L x 102″ W

~10′ L x 102″ W

~18″-24″ H

~40,000 – 150,000lbs+ (5-13+ axles)

Commonly used for tall or oversized industrial machinery, tanks, generators, or equipment that needs to ride low to clear bridges and overpasses.

~10′ L x 102″ W

~24-30′ L x 102″ W

~10′ L x 102″ W

~18″-24″ H

~40,000 – 150,000lbs+ (5-13+ axles)

Best for heavy, self-propelled equipment such as excavators, cranes, tractors, and specialty vehicles that can be driven directly onto the trailer.

~10′ L x 102″ W

~29-50′ L x 102″ W

~10′ L x 102″ W

~18″-24″

~40,000lbs – 100,000lbs+ (multi axles)

Designed for freight that exceeds standard well length, such as long vessels, structural frames, machine bases, or large fabricated components.

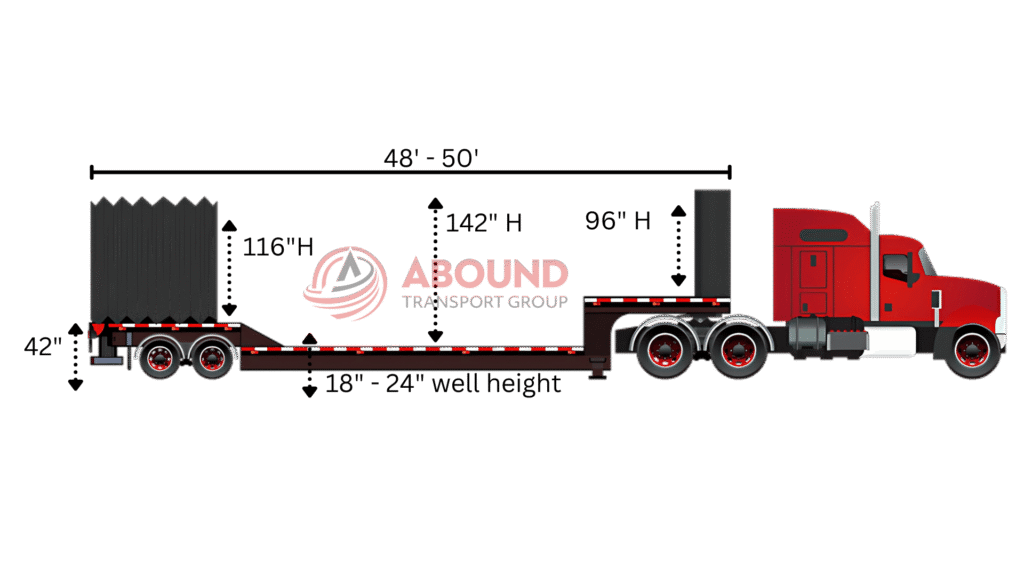

~10′ L x 102″ W x 96″ H

~24-30′ L x 102″ W x 142″ H

~10′ L x 102″ W x 116″ H

~18″-24″ H

~40,000lbs

Ideal for high-value machinery like CNC machines, robotics, and medical or automation equipment that requires full weather protection without tarping.

A look at how we’ve moved low boy shipments recently.

If it’s tall, heavy, self-propelled, or has a high center of gravity, an RGN/lowboy is usually the safest and most compliant choice.

Ideal Industries: Manufacturing, Energy, Mining, Infrastructure, and Construction

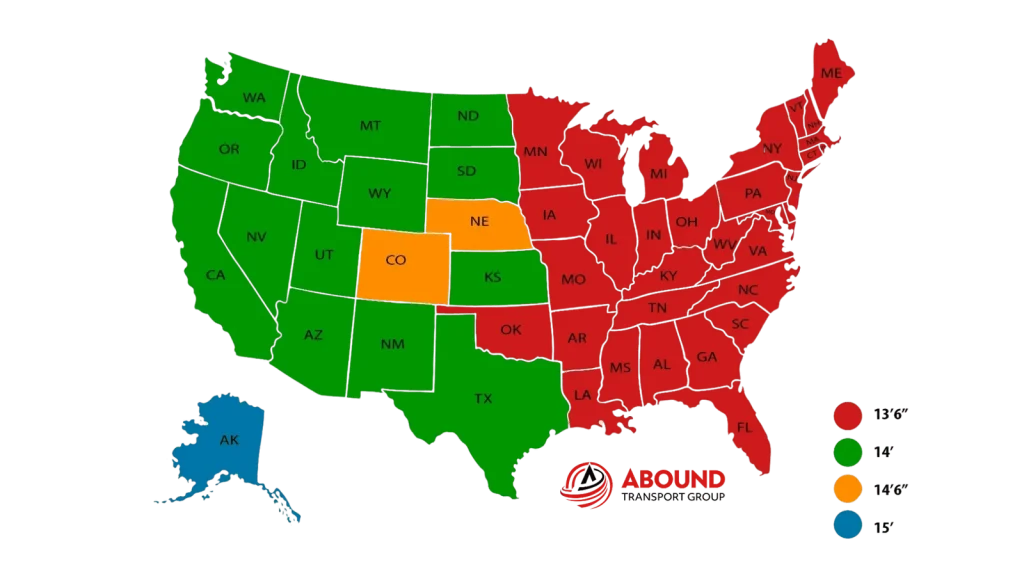

A standard flatbed allows for 8’6″ of cargo height, but legal height limits vary by state. Western states often permit a total height of up to 14 feet, while many eastern states cap it at 13’6″. This means a load that is legal on a flatbed in California may require an overheight permit, or a different trailer such as a step deck, to travel to states like New York.

Our team uses this state-by-state data to plan the most efficient and compliant route for your freight.

Double drop trailers were developed to move extremely tall or heavy equipment that could not travel on flatbeds or step decks without permits. Early versions appeared as heavy industry expanded in the mid-1900s, especially in construction, mining, and agricultural manufacturing. By lowering the center section of the trailer between the front and rear axles, builders created a “well” that could carry tall machinery while staying within legal height limits. Over time, detachable gooseneck designs were introduced, allowing equipment to be driven directly onto the trailer. Today, double drop and RGN trailers are essential for hauling oversized machinery, large industrial components, and specialized freight across North America.

Proper securement ensures safety, compliance, and protection for your freight. All carriers follow FMCSA 393.100 cargo securement regulations. Common Securement Tools:

for machinery, steel, and heavy freight

for finished goods and delicate cargo

to shield against weather and road debris

for balance and elevation

Insights on Shipping, Trailer Types, and Logistics Trends

In most 13’6″ corridors, plan on up to ~12′ freight height in the well (13’6″ minus 18″–24″ deck). We’ll confirm per route.

Yes—via crating/wrapping, partial enclosures, and careful securement. True Conestoga RGN is uncommon; we’ll advise best protection.